|

Marker

Light Rebuild

|

|

|

The

original K D marker lights on the trailer were in bad shape. I could have

opted to replace them with a new tear drop style marker but nothing out

there compares with the quality of these old lights. The replacements

that you find today have plastic lenses and the styling doesn't quite

line up to the original. The interior components on the originals have

rusted out and are non functioning. A new base will be made from .33 inch

thick plexi to replace the rusted old pressed metal originals. My plan

is to make a template out of wood then use a router to cut the new plexi

bases then mount a new mini bayonet socket to hold a 1815 mini bayonet

bulb, 13 volts 4.29 watts .33 amps. On the back side of the new base a

gasket will be installed for a water tight seal against the fixture and

the trailer.

|

|

|

| I have revised the

method for cutting the plexi. Instead of using a router I have opted to

use a jewelers saw and a template made of heavy paper. Another option is

to use aluminum sheeting instead of plexi. The jewelers saw would work well

with this material as well. The first base has been made and works well.

The jewelers saw allows for tighter radiuses and cuts through the material

easily. I will post photos soon. I have ordered the replacement sockets

and bulbs. 20 bulbs, 10 sockets - $17 and change. |

|

|

|

|

|

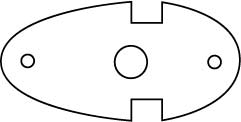

This

is a drawing of the base that is being made.

|

|

|

| This shows the components

which make up the original lights. In order to remove the lights you either

have to grind off the bolt heads which fastens it to the trailer or gain

access from inside the trailer to loosen the nuts which attach to the bolts.

|

|

|

| This is the problem.

The press metal base has rusted and the socket has shorted. |

|

|

| This is the prototype

base. The side clamp cutouts were made smaller in the final run. The bolts

toward the center fasten the base to the trailer. A rubber gasket will fit

between the base and the trailer skin. The metal rim is held in place by

two bolts with nuts recessed into the plexi so that the back side will fit

flush against the trailer. This was done using a router bit in a drill press.

|